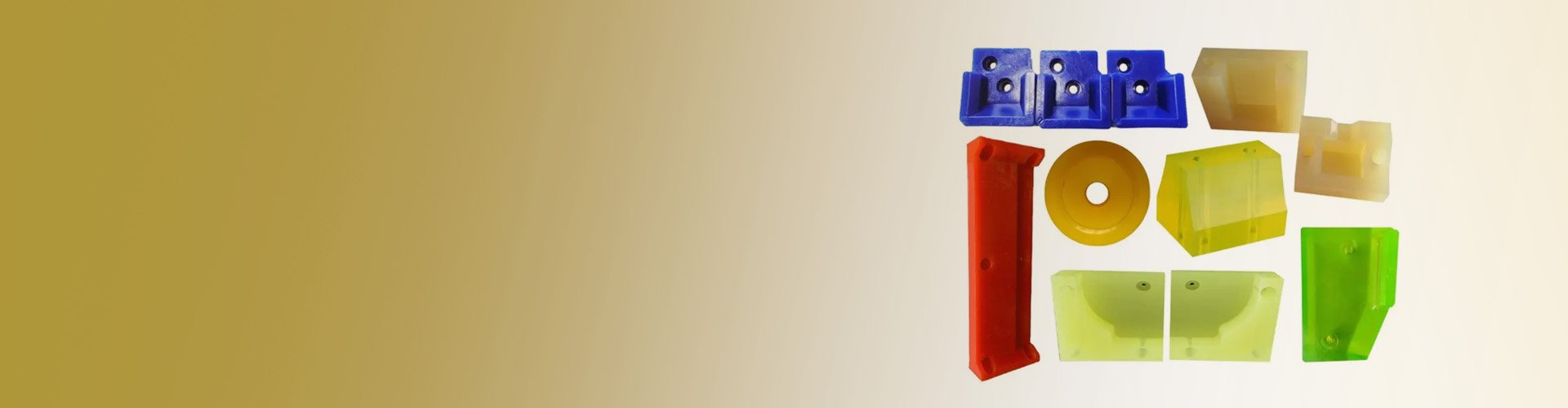

Custom PSU Injection Molding

PSU or also known as polysulfone is a high-strength thermoplastic. It is an amorphous material that has natural transparency. This material is also perfect for injection molding applications.

NDDMold offers custom injection molding services using the highest quality PSU material. We can produce injection molded PSU products in any size, design, and shape. Our team is also capable of achieving 3D or 2D shapes. Just tell us your specifications or drawing.

If you want huge or moderate quantities of PSU molded products at competitive prices, choose NDDMold PSU injection molding services!

Why Choose NDDMold PSU Injection Molding

NDDMold offers up to ±0.07 mm of tolerance. Tighter tolerances are also available upon request.

NDDMold offers various injection molding processes such as over-molding and insert molding.

We ensure to deliver high-quality injection molding PSU products quickly.

To ensure we provide high-quality and defect-free PSU products, we follow strict quality control.

- Excellent stiffness and toughness

- Great electrical insulating properties

- Good thermal stability

- High resistance to hydrolysis, chemicals, oxidizing agents, alkali, hydrocarbon oils, mineral acids, etc.

- Good dielectric properties

- Outstanding resistance to steam sterilization and autoclaving

- Great mechanical strength

- Good dimensional stability

- Resistant to high temperatures

- High compaction resistance

- Good resistance to degradation caused by electron beam or gamma radiation

PSU follows the requirements for gamma sterilizability. It is also chemical-resistant and has hydrolysis stability. Because of that, it can be used for producing medical devices or components such as surgical instruments and more.

Since PSU comply with the FDA standards, it can also be used for producing feeding systems and food processing equipment components.

PSU injection molding is also used for producing electronic and electrical parts such as insulators, capacitors, and many more.

Moreover, it can create appliance components, dental parts, automotive parts, business equipment, and so on.

- Bead Blasting

- Electroplating

- Pad printing

- Mold texturing

There are different grades of polysulfone that are suitable for injection molding. Some of these grades include:

Udel P-1700

This grade has good resistance to hydrocarbon oils and detergents. It is also highly resistant to salt solutions, alkali, and mineral acids.

Udel P-3703

This grade is a high-flow grade commonly used for producing parts with thin walls.

NDDMold also uses PSU with additives such as mineral, glass fibers, and other fillers. If the PSU is reinforced with glass fibers, its tensile strength will increase twice.