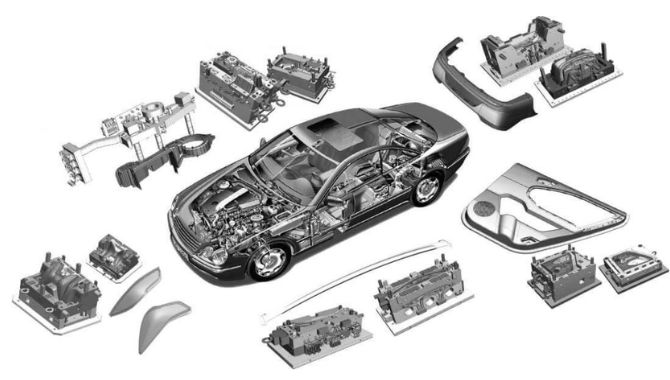

Automotive Injection Molding is a core expertise and a pillar of our manufacturing capabilities at NDDMold. We have established ourselves as a leading provider of automotive injection molding solutions due to our significant, cutting-edge technology, and commitment to perfection. We specialize in the production of a wide range of automotive components utilizing modern injection molding technology at NDDMold. Our modern facilities feature a wide range of injection molding equipment capable of handling components of varying sizes and complexity.

At NDDMold, we apply our knowledge and experience to deal with a diverse range of resources, including but not exclusive to polypropylene (PP), acrylonitrile butadiene styrene (ABS), polyamide (PA), polycarbonate (PC), thermoplastic elastomers (TPE), and more. Our professional engineers and technicians rigorously create and improve molds and equipment to achieve the intended shape, functionality, and aesthetic appeal of automobile components.

From design and engineering assistance through tooling and molding manufacture, prototyping, value-added assembly, quality control, and supply chain management, our automotive injection molding services cover the whole production process. Simply give us your exact needs or sketch and we’ll get started.

Advantages of Choosing NDDMold for Automotive Injection Molding:

- Precision and Quality: We assure exact manufacture and consistent quality in every component, surpassing industry requirements.

- Cost-effectiveness: We optimize the production process by using our experience and cutting-edge technology, resulting in cost-effective solutions for our clients

- Rapid Prototyping: We recognize the value of time-to-market, and our fast prototyping skills enable quick iterations and efficient product development.

- Customization: Our expert staff collaborates closely with customers to produce bespoke solutions that are suited to their particular demands.

- Design for Manufacturability (DFM): Our engineers are well-versed in DFM principles, allowing them to optimize designs for efficient manufacturing while saving money and time.

- Streamline Supply Chain: With our in-house production capabilities, we provide an end-to-end solution, reducing the need for extra suppliers and streamlining customers’ supply chains.

In order to meet the special demands of the automobile sector, NDDMold employs a wide selection of premium materials. We operate with the following materials:

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyamide (PA)

- Polycarbonate (PC)

- Thermoplastic Elastomers (TPE)

- Polyethylene (PE)

- Polyvinyl chloride (PVC)

- Polyurethane (PU)

- 3D Scanning

- CAD or Computer Aided Design

- CAM or Computer Aided Manufacturing

- CNC Machining

- Prototyping Service

- Inventory