Prototyping in NDDMold is an important phase in the product development process that involves the use of innovative techniques and technology to manufacture high-quality mold prototypes. Our prototype experience originates from our thorough grasp of the product manufacturing process and our dedication to producing excellent molds. Our professional team of designers and engineers use cutting-edge software and technologies to build exact and comprehensive 3D models of molds, capturing all critical characteristics and requirements.

The rapid iteration and refinement process at NDDMold demonstrates our dedication to prototyping. We enable informed design decisions and reduce the chance of inaccuracies during later phases of production by offering clients with the ability to examine functionality, performance, and aesthetics through prototypes. For further information or to discuss your prototyping needs, just leave us your message now.

Latest Case

Why choose NDDMold for plastic prototyping?

Quality Matters:

The coveted ISO9001:2015 accreditation recognizes NDDMold’s dedication to quality and excellence in prototype and mold development services. This accreditation indicated our commitment to international quality management system standards. In our quest for perfection, we continue to place an emphasis on quality, customer satisfaction, and constant progress.

Methods used in Prototyping:

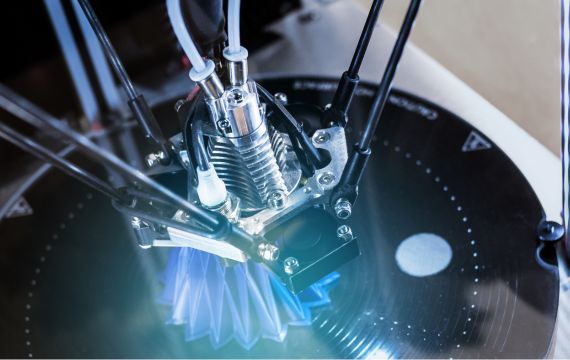

It is a common approach for making prototypes, especially for complicated forms and detailed designs, and it includes setting up layers of different materials (plastics, composite, or metal) based on an electronic 3D model.

It includes techniques such as stereolithography (SLA), selective laser sintering (SLS), and fused deposition modelling (FDM). These approaches employ layer-by-layer additive manufacturing procedures to swiftly manufacture prototypes from digital 3D model.

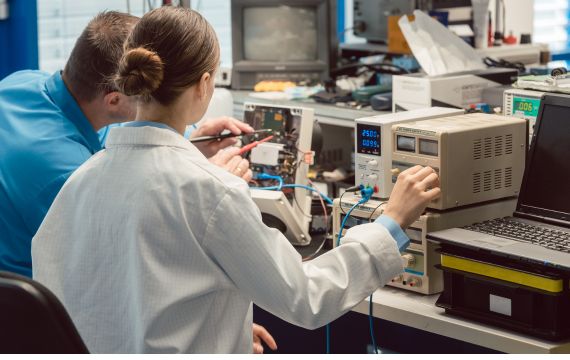

It is a functioning and interactive prototype that demonstrates the main features and functions of a product or service. It is often created early in the product development process to gather input, test assumptions, and evaluate feasibility.

It can take numerous shapes depending on the project’s complexity and purpose. They can range from basic breadboard configurations with individual components wired together to more complicated printed circuit board (PCB) prototype closely match the final product.