At NDDMold, we have skilled designers and design engineers with many years of experience in designing and building molds. Our team can handle simple and even the most difficult design product production.

We also use SolidWorks and other cutting-edge software so our designers can evaluate the product design. They will also give suggestions and offer changes based on the function, application, and other main needs of the product.

Our expert designers can also seek solutions to queries like:

- What is the application of the product?

- How will it be utilized?

- What are the product’s tensile and dimensional requirements?

- Is the product a part of a big assembly or just a stand-alone item?

- Is it necessary for the product to endure chemicals, pressure, and other elements?

- Does the product pass our size and volume requirements?

These questions will help us to produce flawless and perfectly formed products. To answer these questions, in-depth knowledge is required. And our design team can take on all these challenging and complex tasks. They are knowledgeable in the both process of injection molding and mold design. Our design team is going to amaze you with their visually appealing designs.

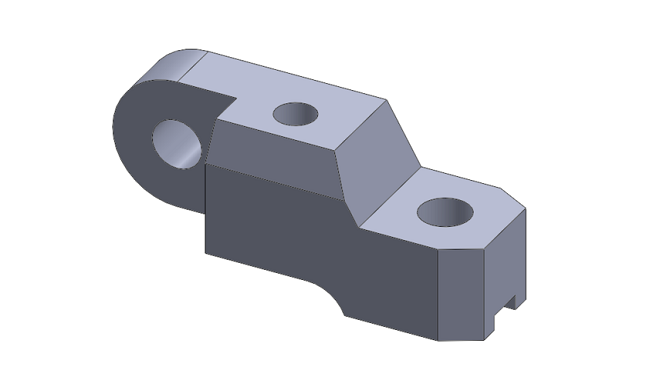

3D Model

NDDMold is capable of turning your drawing into computer-generated and three-dimensional models. We have expert graphic artists and CAD modelers that can bring your product drawing to reality. Our design & development team can provide real and high-quality photos.

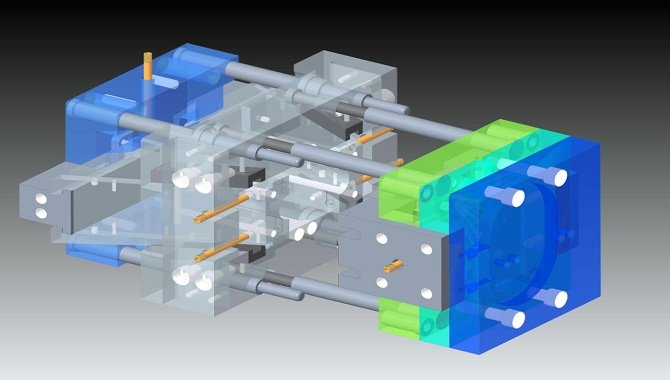

Tool Design & Building

As your professional injection molding partner, we are capable of handling the tool design. We can also create injection molded products with simple or complex geometry.

Additionally, NDDMold follows the SPI (Society of Plastic Industry) standards for building molds. Therefore, you can guarantee the accuracy and quality of our injection molded products.

Factors to Consider in Product Design

Wall Thickness

NDDMold ensures that the products will have uniform wall thickness. Having an even wall thickness will allow the mold to be filled properly. That will also allow the mold to properly cool. If the design has thicker areas, we may hollow them out to ensure their wall uniformity.

Boss Design

Bosses are used in plastic assemblies thru pins or screws. Therefore, the bosses and ribs must have equal thickness. And for the bosses to be ejected, they should be designed with a draft.

Rib Design

The ribs help to strengthen the whole part. They offer stability by supporting the dimensional components and walls.

Our team ensures that the ribs are not wider than the wall thickness. That is because it may sink if the ribs are wider.

We also ensure that the ribs are not overly tall. Ribs should not exceed a maximum of 3 times the wall thickness.

Corner Transitions

The corners of the plastic part should be not in angle form. They should be curvy. Having angles or sharp corners will block the plastic flow.

Weld Lines

When 2 material flows meet, weld lines may form. Due to that, we can design and build the tool in a manner that the part integrity will be not affected.

Gate Placement

The gate placement makes sure that the mold fills properly. It can control the plastic flow so it will be distributed all over the part. The gates can limit the flow length and help prevent flow marks.

Vent Placement

The vents should be placed properly to let the air or gas escape in the cavity. It will also lessen weld lines if the vents are properly set.