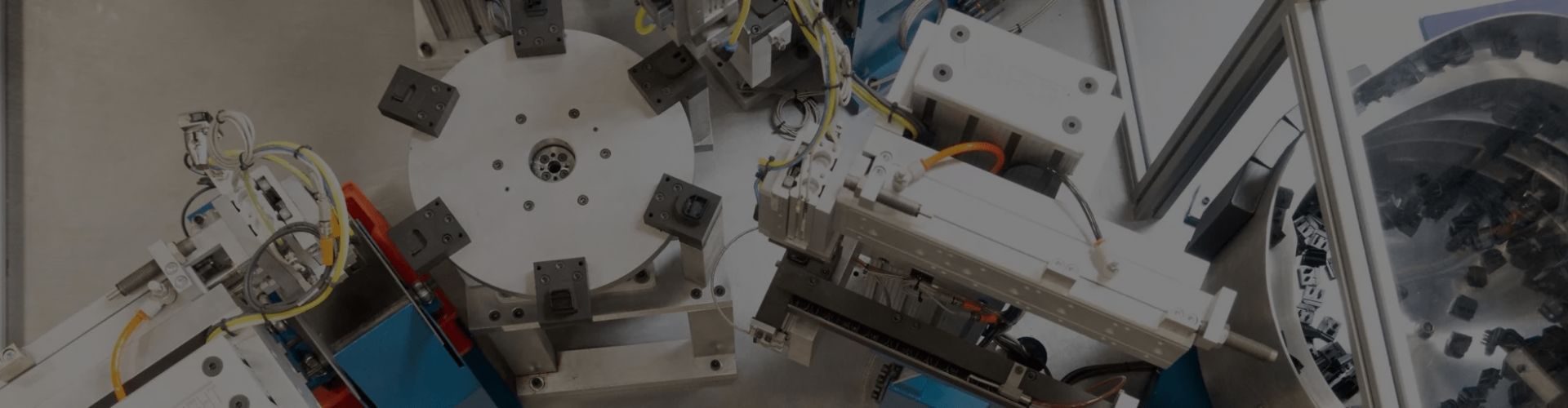

Injection Molding Material Selection

When you select NDDMold for your material needs, you have access to cutting-edge tools and advanced facilities. To ensure the best functionality and dependability for your injection-molded parts, we use innovative testing and analysis procedures to examine each material’s performance characteristics.

Features

Economical production.

Adaptability in design.

Broad range of materials.

Minimal material waste.

Scalability and automated processes.

Extreme repeatability and accuracy.

Stronger and more long-lasting components.

Post-processing demands are lessened.

Common Material Option

HIPS-High Impact Polystyrene

LDPE-Low-Density Polyethylene

ABS-Acrylonitrile Butadiene Styrene

PP-Polypropylene

PE-Polyethylene

PS-Polystyrene

Nylon-Polyamide

PC-Polycarbonate

POM-Polyoxymethylene

PETG-Polyethylene terephthalate-glycol

Suitable Applications of Injection Molding

- Furniture

- Components for automobiles

- Customer products

- Healthcare equipment

- Packagers’ industry

- Both defense and aviation

- Industrial and commercial toolkits

- Construction and building

- Electronic and electric parts

Choosing the Right Material: Some Things to Think About

- Recognize the technical requirements.

- Examine about the chemistry of the area.

- Consider the needed temperature.

- Take into account the projected production level.

- Analyze the complexity of the design.

- The price of the materials plays a big role in the decision-making process.

- Identify any regulatory requirements that your product must adhere to.

- Think about the finished product’s aesthetic attractiveness.

- Check whether the information is available and accessible.

- Evaluate how the materials you choose will affect the environment.